Copper Strip Corrosion Test Vessel – 22150-5

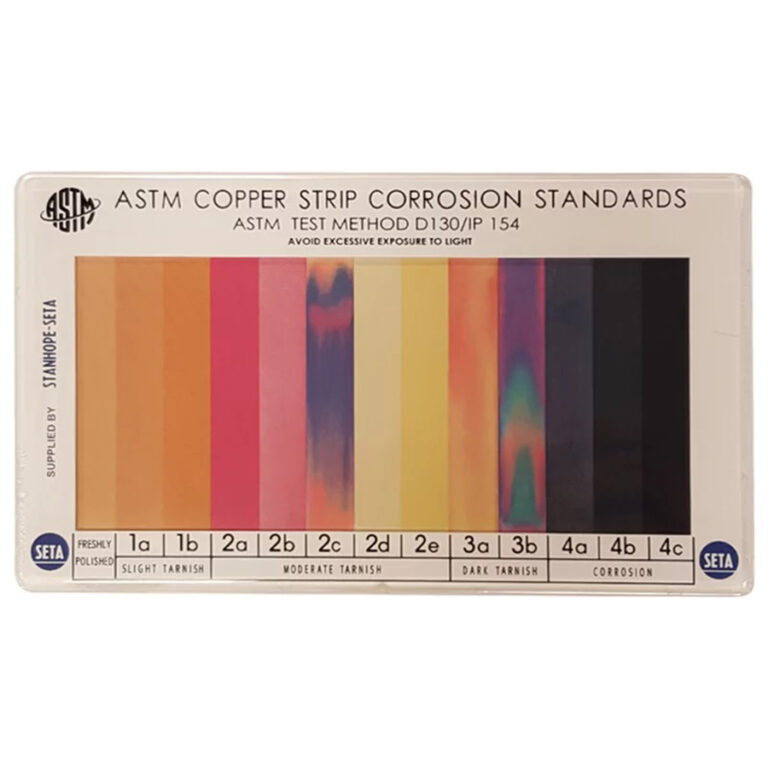

Detects the corrosiveness to copper of liquefied petroleum gases (LPG). A polished copper strip is immersed in an LPG sample for one hour at 37.8 °C (100 °F) then removed and rated against an ASTM-IP Standard.

Methods

ASTM D1838, IP 411, BS EN ISO 6251 & BS 2000-411 & ISO 6251

Details

Comprises polished stainless steel vessel with two stainless steel needle valves, dip tube and ‘O’ ring sealed cap. 70 bar (1000 psi) test pressure.

Certification: Pressure tested and supplied with a Works Test Certificate

Specifications

| Weight | 1.8 kg |